Diecasting has been a major component of Malaysia’s manufacturing sector, and is playing an important part in Malaysia’s economic growth and production capabilities. The highly sophisticated process involves the injection of molten metal into a mold in order to make intricate components which are vital for the production of precision components that are used in a variety of sectors. Diecasting in Malaysia has risen substantially over the last couple of years due to advancements in technology, an experienced workforce, and strategically-planned actions by the government. This growth in the industry is part of Malaysia’s larger industrial change which has placed the nation as an important participant within the global industrial landscape.

Diecasting’s beginnings throughout Malaysia are traceable to the middle of 20th century an era marked by an explosion of industry and growth in the economy. Diecasting was initially used mostly to produce essential metal parts to be used locally. As Malaysia’s economy developed and industrialized, need for more sophisticated and precision diecast products exploded. The shift was due to the electronics and automotive industries that require durable quality parts to make their goods. In recognition of the potential for diecasting for industrial development and boost productivity, the Malaysian government enacted strategies to encourage the development of this industry, such as investing in infrastructure as well as technology.

Technology advancements have played a key role in accelerating the development of the diecasting industry in Malaysia. The use of computer-aided designing (CAD) as well as computer-aided manufacturing (CAM) technology has transformed the process of production, giving more precision and effectiveness. Diecasting methods that are modern including squeeze casting and vacuum diecasting has improved the performance and longevity of parts made from diecast which makes them ideal to be used in a wider range of uses. In addition, advancements in material research have resulted in the creation of alloys that have improved properties that have expanded the possibilities of using diecast products. This technological advancement has enabled Malaysian diecasters to be able to meet the high standards for quality of the international market.

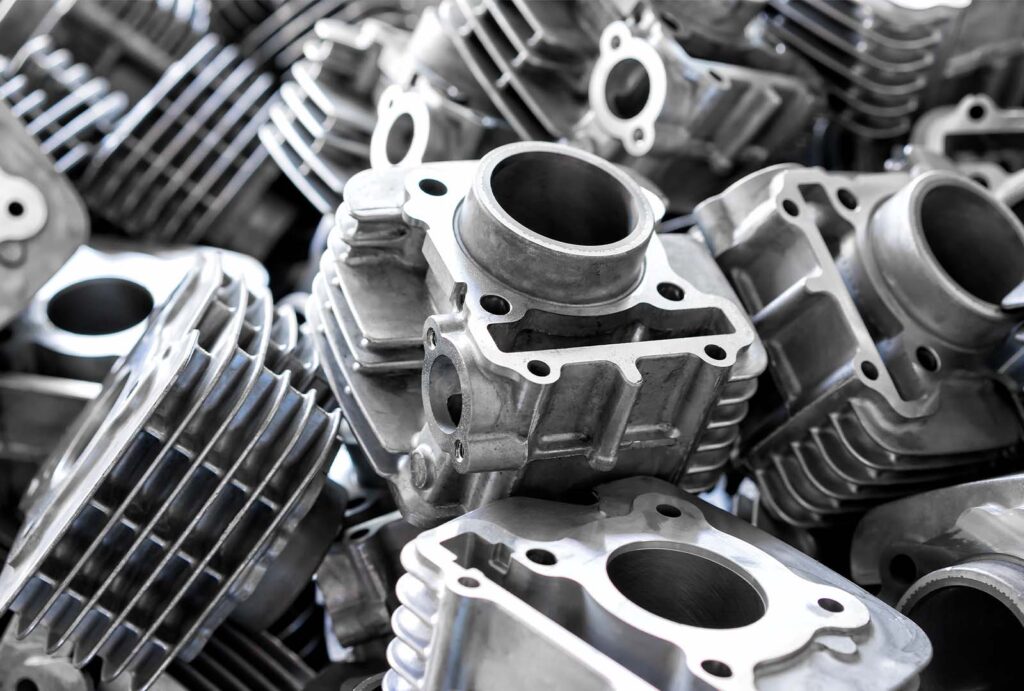

Automotive industry is recognized as one of the major beneficiaries of the diecasting capabilities in Malaysia. Diecast components play a crucial role in manufacturing various automotive components like engines, transmission cases as well as structural parts. Precision, durability and light weight of diecast components makes them suitable for use in automotive industries in which performance and dependability are essential. Malaysia’s strategically located location, combined with its strong infrastructure has drawn a variety of global automobile companies, further increasing the demand for diecast parts. This has led to Malaysia is now an essential actor in the automotive supply chain and has benefited from the expertise of its diecasting industry to help the growth of the automotive industry.

In addition to the auto industry The electronics sector also heavily rely on precision die casting Malaysia. The process can be utilized to create highly precise and intricate electronic components including connectors, housings, and heat sinks. The growing market for consumer electronics that is driven by the growing popularity of laptops, smartphones and various other electronic devices is creating huge potential in the market for Malaysian diecasters. Through maintaining the highest standards of quality and using advanced manufacturing methods, Malaysia has established itself as a trusted supplier of diecast products to the electronics industry worldwide. The success of Malaysia is a testament to its ability to be flexible to changing industry trends and satisfy the changing demands of the high-tech industry.

If we look to the in the future, prospects for the diecasting industry in Malaysia seem promising. As the trend continues to shift towards lighter and efficient vehicles is likely to increase demand for diecast aluminum parts within the automotive field. In addition, the explosive growth of the electronics sector is expected to continue creating new potential for the diecast industry. To take advantage of these opportunities, Malaysian diecasters must continue to invest in new ideas and technological advancement, with a focus on improving effectiveness and sustainable. The government’s support in research and development in conjunction with a more conducive economic environment will be vital to maintaining this industry’s expansion. If Malaysia takes advantage of these opportunities, Malaysia will be able to consolidate its status as a leading player in the world market for diecasting.

Diecasting, in the end, has been a key component of Malaysia’s manufacturing industry which is a major factor in the development of important industries like electronic and automotive. The development of the diecasting business, driven by advancements in technology as well as strategic plans which has allowed Malaysia to be competitive at a global level. With the need for top-quality diecast products continues to increase and the prospects for diecasting in Malaysia appears promising. With the right investment in new technology and ensuring high quality standard, Malaysian diecasters can seize many opportunities to contribute to the economic growth of the nation. Diecasting’s history in Malaysia is an example of Malaysia’s dedication to high-tech advancement and innovation.